AlfaNova Fusion Bonded Plate

Model Number

AlfaNova 27 - AlfaNova 52 - AlfaNova 76Product Description

100% stainless steel components, bonded together using Alfa Lavals patented technology, AlfaFusion, resulting in exceptionally high mechanical and thermal fatigue resistance.

Well suited to applications requiring cleanliness, hygiene and corrosion resistance.

AlfaNova Fusion Bonded Plate

Model Number

AlfaNova 27 - AlfaNova 52 - AlfaNova 76Product Description

100% stainless steel components, bonded together using Alfa Lavals patented technology, AlfaFusion, resulting in exceptionally high mechanical and thermal fatigue resistance.

Well suited to applications requiring cleanliness, hygiene and corrosion resistance.

Dual Plate – Lugged

Model Number

Product Description

Locating lugs, to fit PN6/10/16 and ANSI150

Stainless steel plates, shaft and springs

Fully lined EPDM

Body epoxy coated

DN40/65 GGG40 ductile iron

DN80/200 GG25 cast iron

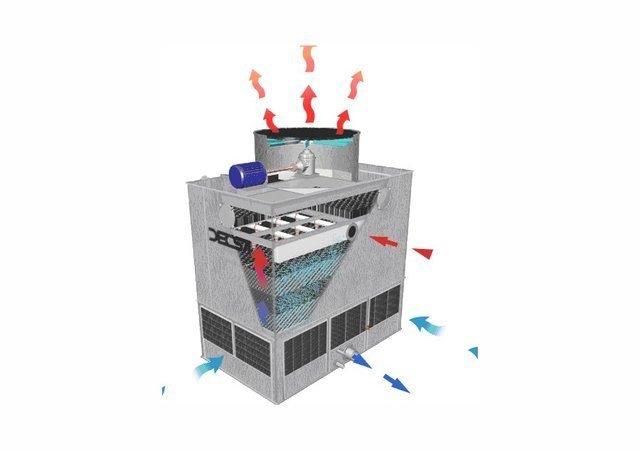

TMA Series Axial Open Circuit Cooling Tower

Model Number

TMAProduct Description

Open circuit metal cooling tower with Z725 galvanized steel and axial fans designed for cooling water in civil and industrial fields. Ideal for use in an industrial setting for the plastics, chemicals, pharmaceutical, automotive and energy sector and air conditioning for hospitals and the commercial services sector.

Low operating costs, thanks to the limited energy consumption of the motors powering the fans

Structure in self-supporting high strength galvanized sheet steel Z725 (725g/m2)

Easy and fast maintenance of spare parts and moving elements

Wide power range. Easy and cost-advantageous transport and installation of the sections without the need for exceptional trailer transport

Versions:

Exchange pack with differentiated sections (standard, expanded Splash)

Silenced (Axilent and Axilent Plus)

Direct coupling between motor and fans and angle drive with oil-bath transmission

Protection with painting DecsaCOATING (external) or DecsaCOATING PLUS (internal & external)

Number of Models: 56

Heat Rejection: from 547 to 8664 kW

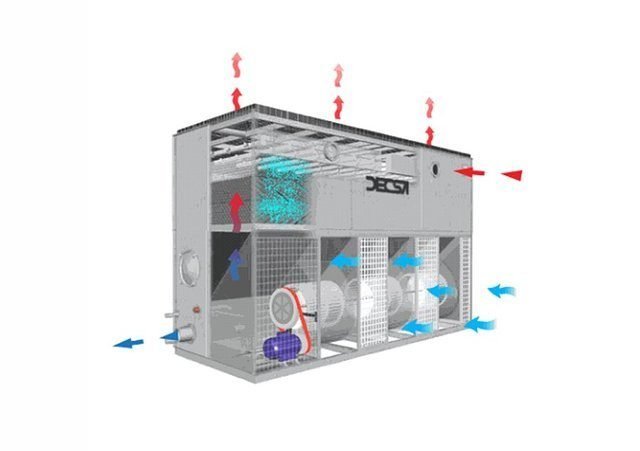

TMR Series Centrifugal Open Circuit Cooling Tower

Model Number

TMRProduct Description

Open circuit cooling tower with casing in Z725 galvanized steel and centrifugal fans, designed for cooling of water in civil and industrial fields. Ideal for industrial use for the plastics, chemicals, pharmaceutical, automotive and energy sector and air conditioning for hospitals, commercial services sector, and in settings where a reduced sound output is paramount.

Very quiet noise level provided thanks to the centrifugal fans

Structure in self-supporting and high-resistant galvanised steel in Z725 galvanised sheet (725g/mq)

Silencers on inlet and outlet

Fast and east maintenance of spare part and moving elements

Broad power range. Easy and cost-advantageous transport and installation of the sections with no need for exceptional trailer transport

Versions:

Exchange pack with different sections (Standard, extended Splash)

Protection with painting DecsaCOATING (external) or DecsaCOATING PLUS (internal & external)

Additional silencers on air intake and discharge

Basin section accessible with wide doors

Number of models: 79

Heat Rejection: from 100 to 6153 kW

PSHE Evaporator

Model Number

Product Description

Vahterus Plate & Shell Heat Exchangers

These have many benefits for refrigeration applications such as evaporators, condensers, cascade heat exchangers, desuperheaters and oil coolers.

PSHE’s are effective, durable and versatile due to their unique shell construction, together with fully welded plates. This makes PSHE’s ideal, having compact sizes and requiring low refrigerant charges.

Vahterus heat exchangers are suitable for all refrigerants, especially natural media such as ammonia and carbon dioxide.

U-Turn Seperator

Product Description

Alfa Laval plate heat exchanger technology enables efficient evaporation with small temperature approaches. Alfa Laval designed the U-Turn separator to ensure efficiency and achieve smaller overall dimensions for easier and more compact installations.

The Case Story below explains how the UK’s Homerton University Hospital switched to a new ammonia-based cooling system and increased cooling capacity by 50 percent. They also significantly reduced the refrigerant charge, and achieved a reduced environmental impact.

The Alfa Laval U-turn Separator brochure below details how utilising the best of Alfa Laval’s plate heat exchanger technology, the compact U-Turn solution delivers maximum separation efficiency and energy efficiency.

U-Turn Separator

Model Number

Product Description

Alfa Laval plate heat exchanger technology enables efficient evaporation with small temperature approaches. Alfa Laval designed the U-Turn separator to ensure efficiency and achieve smaller overall dimensions for easier and more compact installations.

P Series Oil Cooler

Model Number

Product Description

High quality plate-finned oil coolers with large extended surface resulting in a compact design giving low weight, small oil and water volumes with low pressure drops.

Available as either thermosyphon (1P) or liquid cooled (2P) design, with removable tube bundle for ease of maintenance.

PSHE Evaporator with External Separator

Model Number

Product Description

Evaporators

The versatility of Vahterus PSHE’s is demonstrated particularly in evaporator applications. PHSE can be used as highly efficient flooded or direct expansion evaporators, due to low pressure drop and high heat transfer. Fully welded circular plates and a protective outer shell, guarantees safety for the end user. This construction also ensures high integrity and durability.

Flooded Evaporators

Refrigerants: NH3, CO2, R404A, R134a, propane etc

Capacity range: 5-20,000kW

Small refrigerant charge

Low evaporative side pressure drop

Flexible construction

High efficiency

Direct Expansion Evaporators

Capacity range: 5-1500kW

Can be used for all refrigerants